Type:公司新聞 Release Time:2023-06-12

Cerawei Technology (JIangxi) Co.,Ltd is a high-tech ceramic additive manufacturing company jointly invested and incorporated by AMSKY (China), AGCC Corporation (Japan) and Roland DG (Japan).

The company focuses on ceramic 3D printing equipment, and jointly researches and develops the raw material, platinum sand, with AGCC Corporation of Japan. Now, we provide ceramic 3D printing equipment and supporting materials, ceramic 3D printing services, ceramic 3D printing technology education and training and other series of solutions to customers in the market, and make every effort to become the world's leading integrated solution provider of ceramic intelligent manufacturing.

We have modern industrial equipment for rapid prototyping (ceramic 3D printers) and experienced research-oriented talents in the high-precision materials industry, and have obtained a number of patents in the ceramic 3D printing industry.

In 2019, the investment company set up the first experimental production line in Hangzhou, combining the advanced technology and materials of Japan AGCC (platinum sand) with the technology of ceramic 3D printing equipment to successfully realize the manufacturing technology of precision ceramics and complex ceramics.

Microceramic Technology dedicates this advanced technology to the field of industrial casting, making a breakthrough in the limitations of traditional production processes, creating new product configurations and functions, enabling fast and stable sample production, efficient quality molding, optimizing enterprise labor allocation, reducing the chance of trial and error in product design and production, significantly reducing enterprise development costs, and enhancing the core competitiveness of enterprises.

Core Equipment

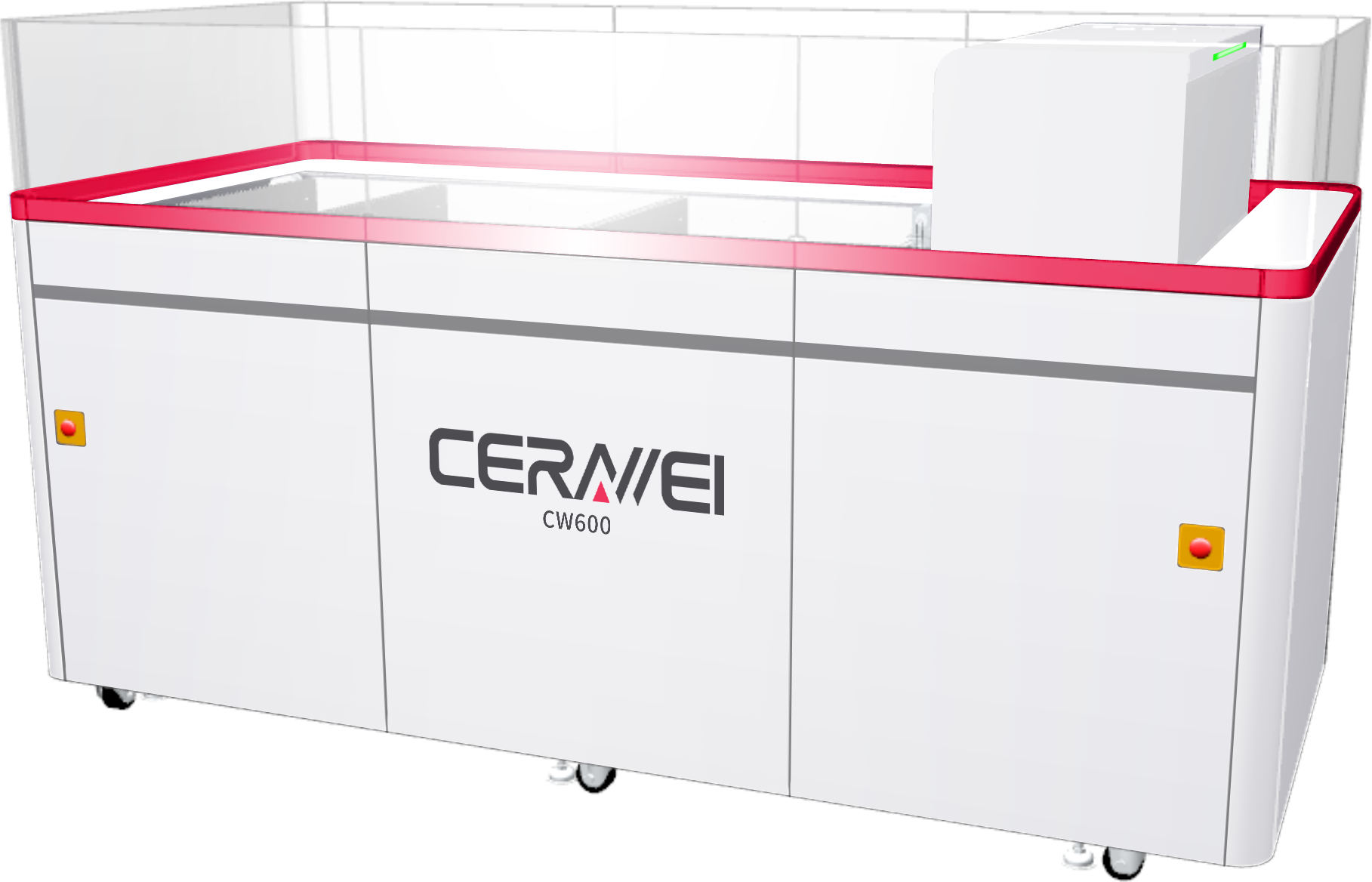

We have modern industrial equipment for rapid prototyping (ceramic 3D printers) and have obtained several patents in the ceramic 3D printing industry, of which CW400, CW600 and CW1000 are the core equipment.

CW400

CW600

CW1000

Core Materials

We have developed the raw material, platinum sand, in collaboration with AGCC Co.

The main raw material is artificial sand "FINE-BzTM" and "special inorganic binder material", which is the best material for 3D printing process in terms of particle size and fluidity.

? Artificial sand "FINE-BzTM

Ceramic spherical microparticles made by electrofusion technology, with high refractoriness, high strength, and high thermal conductivity, ideal for use in casting sands.

Main chemical composition: AI2O380%, ZrO210%, SiO29%

Main containing minerals: Corundum, Baddeleyite

Central particle diameter: 50~30μm

? "Special inorganic binder material

Special inorganic binder material specially developed with Al2O3 and CaO as the main ingredients, and inorganic binder using plasticized refractory materials.